Description

For a description of brake fade and the performance of the standard braking system compared to ventilated disks, check out the Brakes page for more info.

The calipers used in these kits are brand new. They have been carefully selected to have a piston diameter comparable to that of the original Gemini calipers. Due to this, the brake fluid demand is similar to standard, and no master cylinder modifications or upgrades are required. The factory brake booster and master cylinder are a great combination with this kit, making it a truly bolt on set up. NOTE: Some conversions available from other suppliers using different calipers require a replacement 1″ (piston diameter) master cylinder because the standard Gemini master cylinder does not supply enough fluid volume. Our kit uses the standard master cylinder and has excellent pedal feel.

The combination of the size of the piston in the caliper, the diameter of the brake rotor, and the swept area of the pad, all add up to a level of brake retardation for the front of the vehicle, which is more than standard, but not that much greater that the vehicle braking balance is upset. Compared to really large 300mm units for example, which would be over braked on the front, unless doing a similar disc brake upgrade on the rear.

Remember though that as the temps start to skyrocket whilst circuit racing, the stock brakes (solid discs) quickly overheat, and the small area of the stock Gemini brake pads will only give a short service life. These larger ventilated rotors will dissipate huge amounts of heat by comparison, plus the area of the brake pads in the new calipers is about 3-4 times greater, meaning much longer pad life, especially whilst racing.

You also use the original Gemini hub which means no changing of wheel stud patterns or offsets. You keep the original 4×100 stud pattern and can use alloy wheels made for a Gemini or similar, as long as they are at least 15″ in diameter. This also means that if you decide to sell you car, and want to keep the brake upgrade kit, you can simply unbolt it and install the factory disks and calipers easily, as no modifications to the vehicle are required.

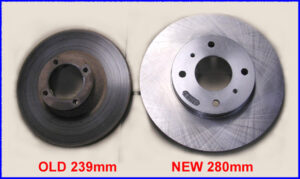

The rotors used in this kits are 280mm diameter units, 22mm thick and are ventilated. The rotors are machined to bolt onto the original Gemini hub using new cone lock nuts and washers supplied. The photo below shows the standard solid Gemini rotor compared to the larger ventilated unit.

Also supplied are big single piston floating calipers and new semi-metallic brake pads to suit. The calipers are machined to bolt onto the original Gemini stub axle bracket.

The ceramic/copper Protex Ultra pads provide a much higher temperature operating range compared to normal OEM brake pads. Also, due to their design, they are very effective when cold, unlike some race pads that don’t generate much friction with the rotor surface until they warm up.

The higher operating temperature range means that at the higher brake component temps experienced whilst racing, these pads continue to bite hard, and resist fading and surface glazing. Other lower spec pads can deteriorate when they get hot, as the bonding chemicals (glue) that holds the pad’s friction material together seeps out of the pad, and glazes the mating surface of the disk and pad. This leads to reduced braking torque, and also causes the annoying brake squeal many cars get.

Kit includes:

| 2 x new 280mm diameter ventilated rotors, re-drilled to bolt onto original Gemini hub.

(optional DBA T2 slotted rotors available – additional $300) |

|

| 2 x fully re-manufactured PBR big single piston floating calipers, machined to bolt to Gemini stub axle. | |

| Set of new Protex Ultra brake pads. | |

| 8 x new M10 bolts & cone lock nuts and washers to secure rotor to hub. | |

| 2 x new Protex brake hoses to connect Gemini brake line at inner guard to new caliper. | |

| New banjo bolt fittings and copper washers for brake hose connection to calipers. | |

| 2 x brake hose fasteners to secure new hoses to original inner guard hose bracket. | |

| Complete simple to follow fitting instructions that guide you through the installation. |

The installation is literally a bolt in job. Just follow the comprehensive instructions provided, bolt the hardware on the vehicle, bleed the brakes, and that’s it!

When braking hard, approximately 60%-80% of total braking (depends on weight transfer, heat and brake specifications) is done by the front brakes. As the front brakes are required to do the majority of the work, they generate an enormous amount of heat. A larger disk (within reason) can be used to dissipate that heat more effectively.

When using the smaller Option 2 Performance brake kit on our race car, we were still using the factory rear drum brakes. Even after the rear drum brake’s performance starts to decline after a few hot laps, both from brake fade and from simply wearing out of adjustment, the front disks have heaps of stopping power and seem to pull the car up all by themselves. We can almost (the car’s getting a bit too powerful now) race all day like this without experiencing severe brake fade, and the car is no slow coach! However when racing with around 250hp on your typical circuit like Winton or Philip Island, the brakes were getting too hot, so if you have 250hp or more, and getting into circuit racing, then this Option #3 Big Brake kit would be better suited, and obviously a rear disc upgrade would be fantastic as well.

ADD TO CART

ADD TO CART

Reviews

There are no reviews yet.