Description

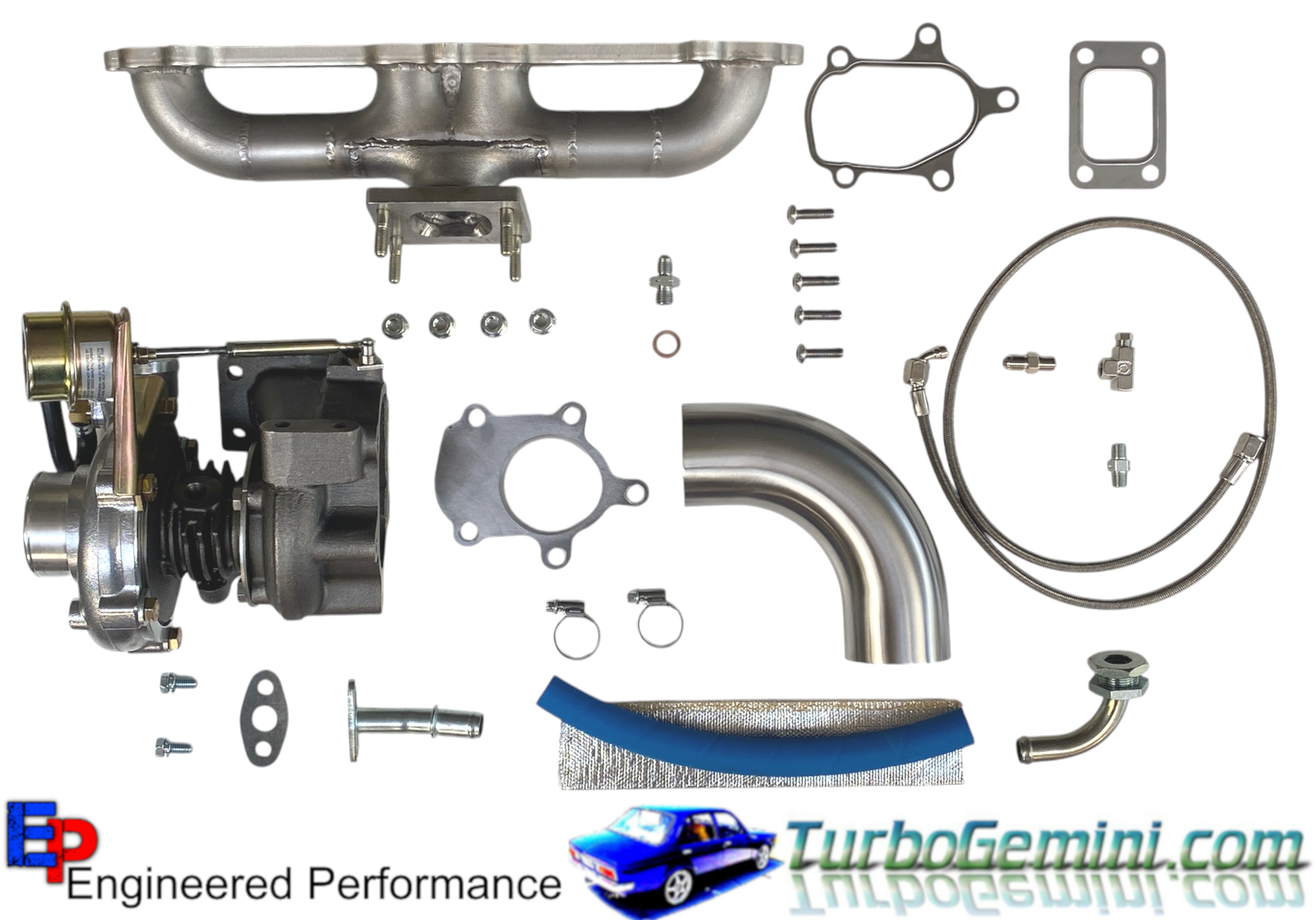

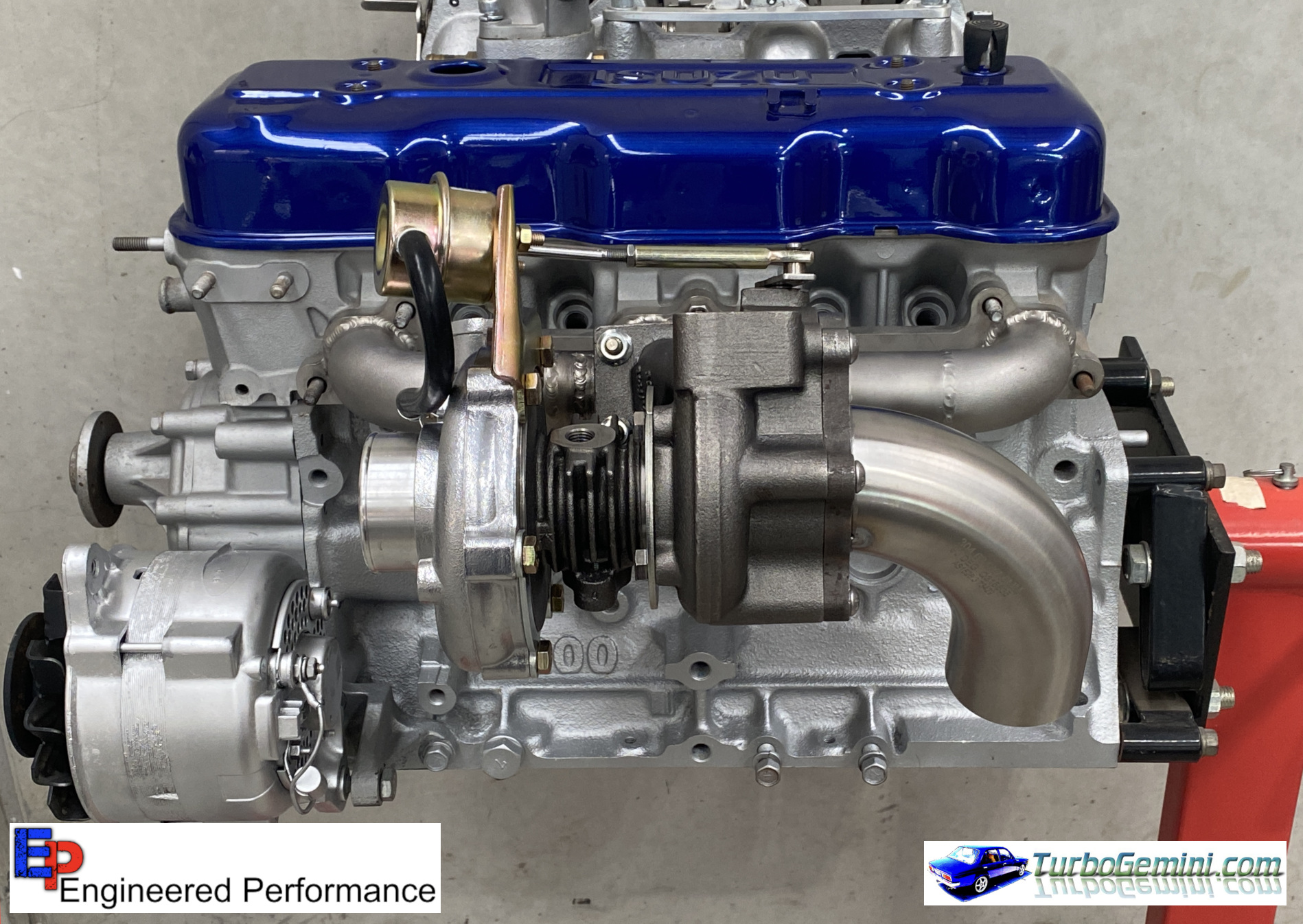

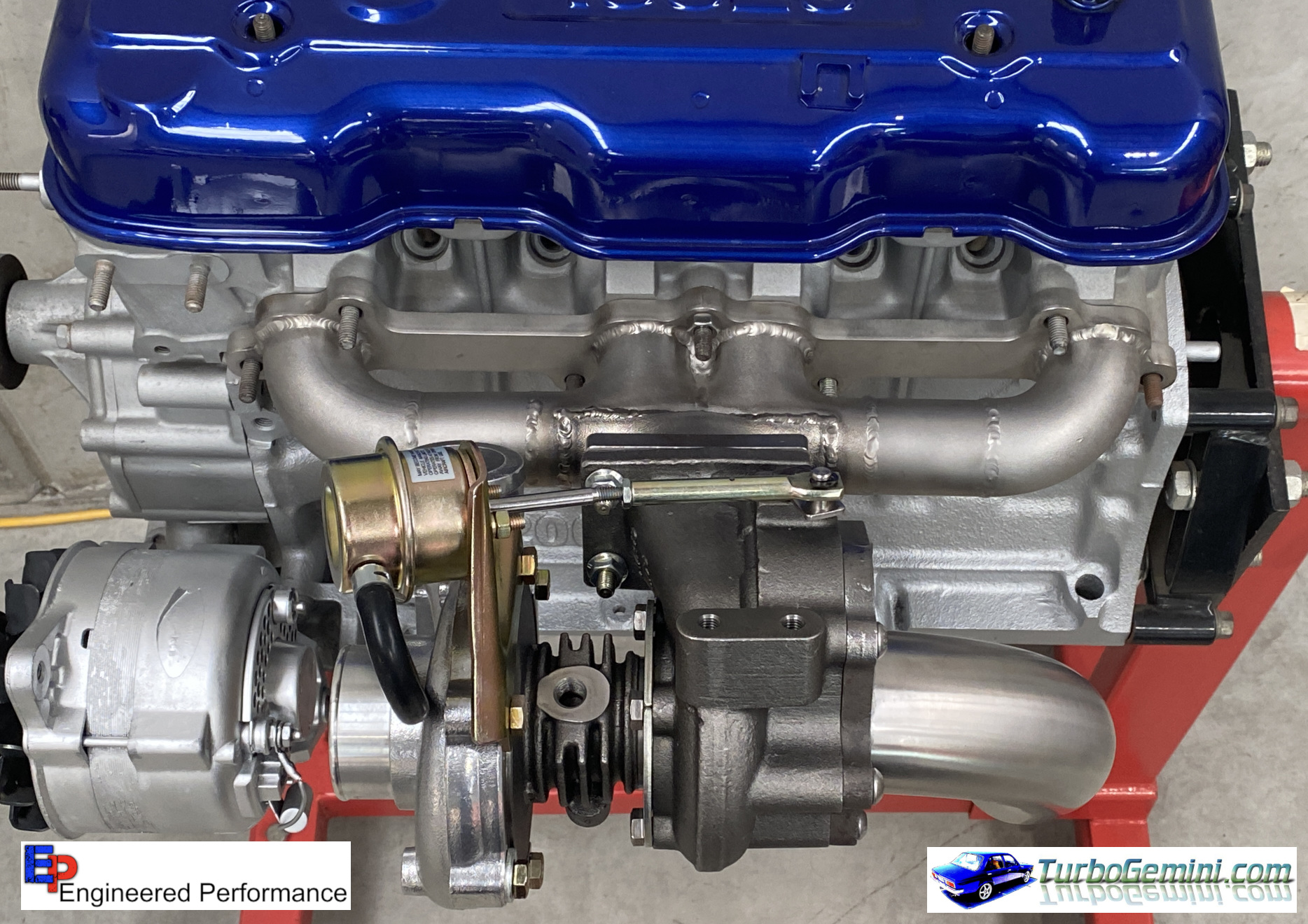

This is a bolt on kit that comes will all the little parts that are needed, like gaskets, hose clamps, studs, nuts and bolts, etc. There is no fabrication necessary apart from welding the exhaust dump pipe and installing the oil drain fitting to the engine sump.

The kit is designed for an Isuzu G series engine (G161, G180, G200) fitted to a Holden Gemini, models TX-TG, Jackaroo, Rodeo, etc. This kit also bolt onto 4Z series engines (4ZC1. 4ZD1, 4ZE1) such as found in Piazza and later model Rodeos as they share the same exhaust manifold stud pattern.

For anything from stock or mild 1600cc engines, 1800cc, or worked 2 litre engines, this is an ideal kit which includes a small frame turbo that will spool up quickly for fast boost response, but with a turbo and manifold that are still capable of producing up to 250hp.

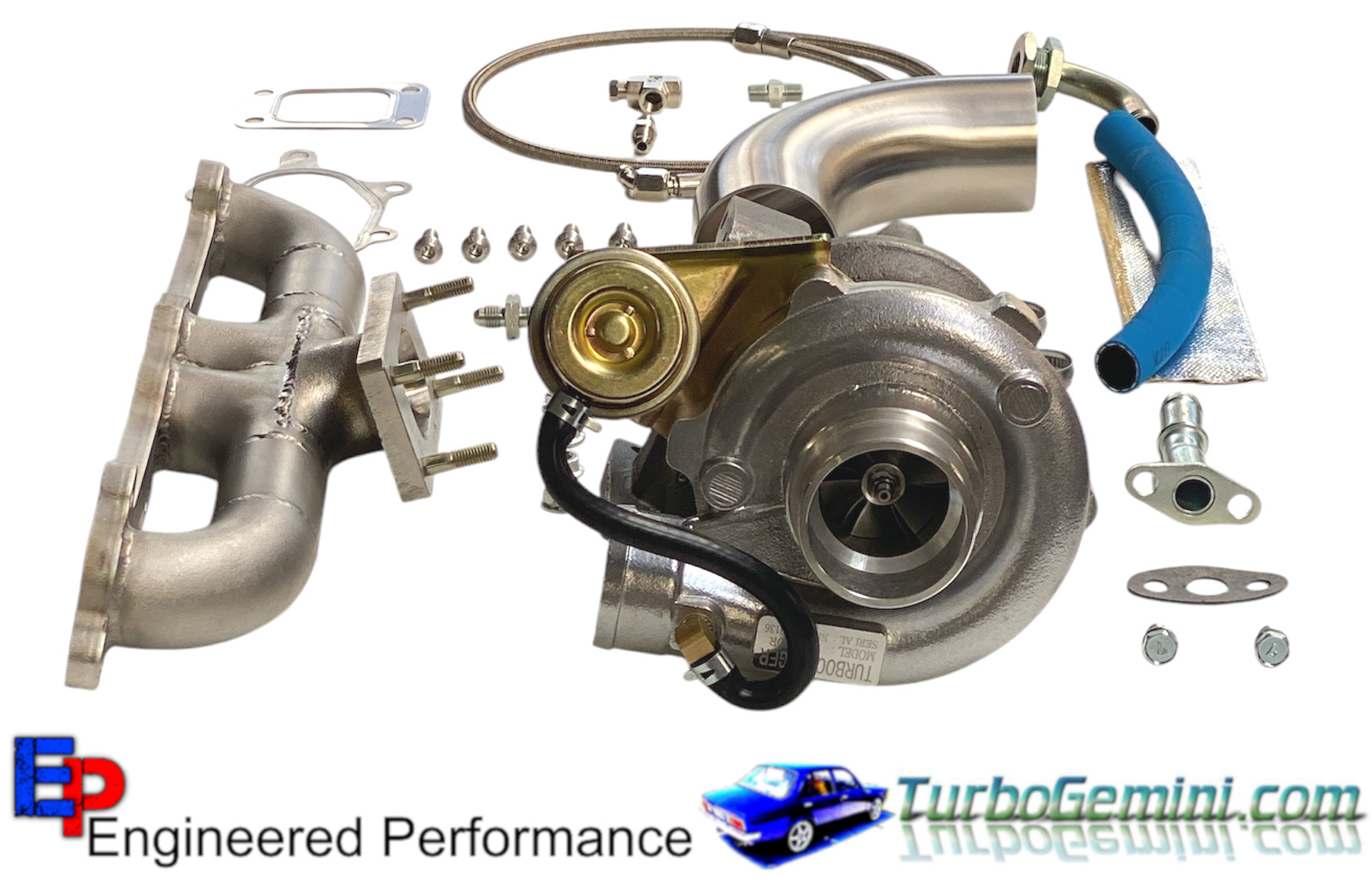

TURBO EXHAUST MANIFOLD – Stainless Steel log style – T25 flange

The exhaust manifold supplied is a brand new TurboGemini stainless steel log manifold with T25 flange manifold. (Note: T2, T25, T28, GT2X flanges are all the same). These TurboGemini manifolds have been designed to support over 250hp while still maintaining fast turbo boost response. They are compact, minimising internal volume, and therefore minimising turbo lag. Manufactured from laser cut 12mm stainless header and turbo flanges, and using schedule 10 stainless steam pipe fittings, with typical 2.7mm – 3.0mm wall thickness. These are a very strong manifold, that won’t crack and fatigue after countless heat cycles.

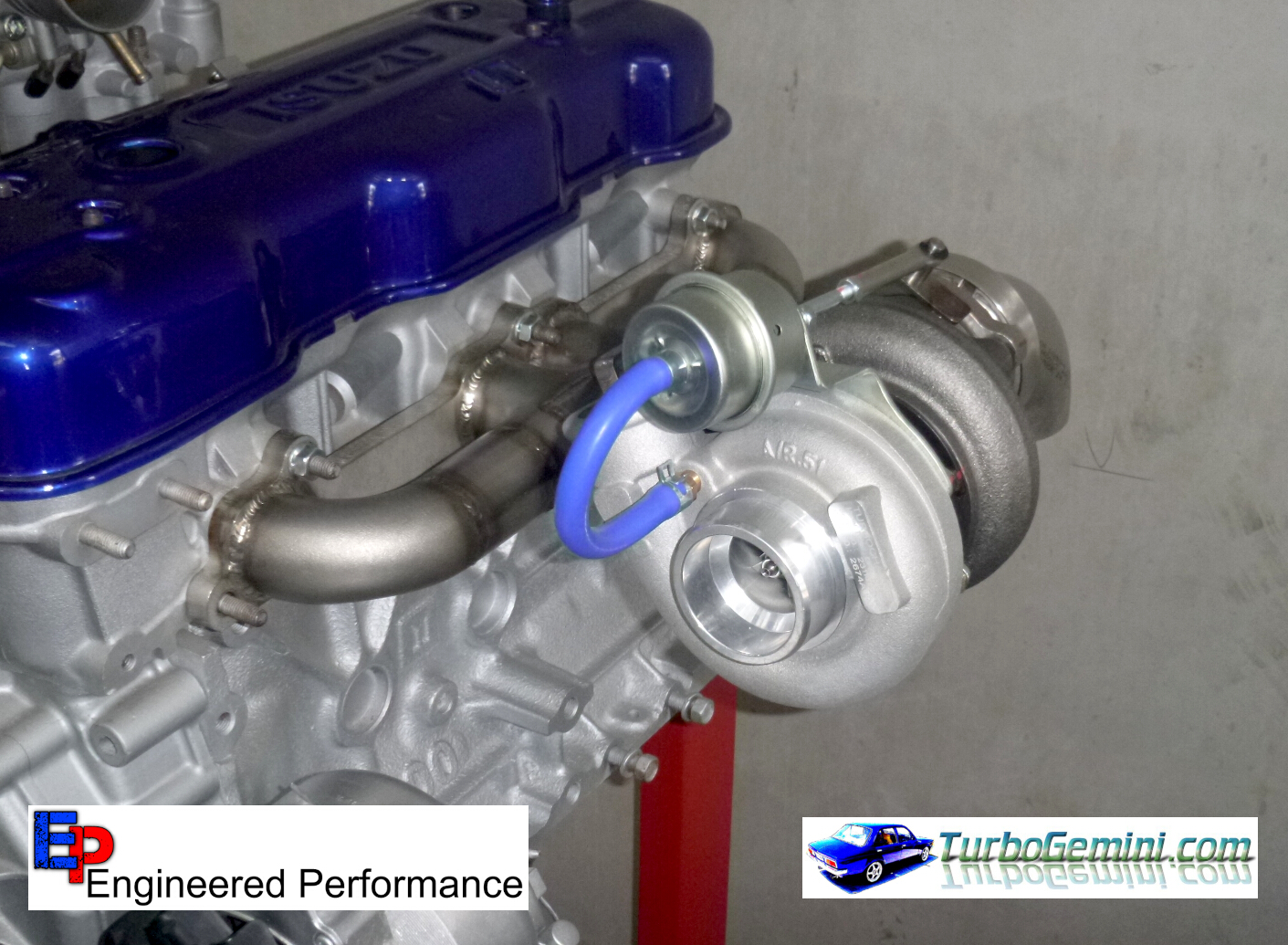

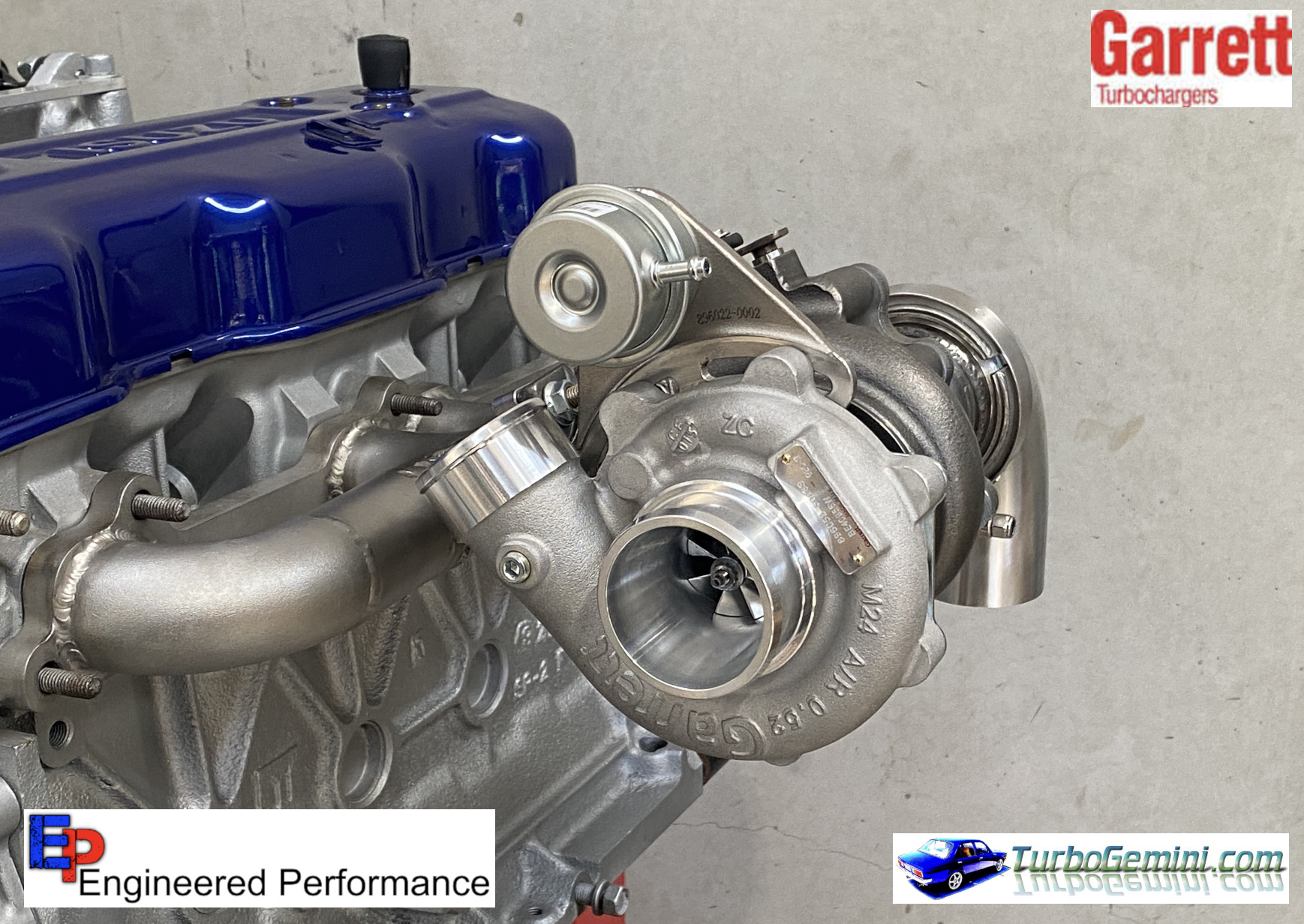

TURBOCHARGER – Chinese T25 Turbo

The turbo is a T25 spec Chinese manufactured turbo that we offer as a lower cost alternative to the premium Garrett turbo. We have gone to a lot of time and expense to find a factory that makes a quality turbo, as opposed to some of the poor quality units you can buy at the lower end of the price scale. We have used dozens of this model turbos in our kits without any issues.

The T25 turbo is oil cooled, with a journal bearing centre housing, and internal wastegate. The unit can support 250hp. To achieve the 250hp rating, the turbos are slightly larger than the equivalent Garrett 250hp turbo. They use a larger compressor and turbine wheel, so they have good flow potential, however the exhaust housing A/R is kept small to promote fast spool up, so we believe the real world turbo lag difference is minimal. Specs are:

| NOTE: the compressor housing can be clocked to suit either a cross over pipe or an intercooler install. | |

| T25 exhaust flange | |

| 60mm Compressor – 0.49 A/R – 60 Trim | |

| 53mm Turbine – Exhaust A/R = 0.49 – 76 Trim | |

| 60mm compressor housing inlet / 50mm (2.0″) outlet | |

| Oil cooled | |

| Standard supplied adjustable wastegate = 7/8psi, (note: adjustment will give 1-2psi variation only) |

DUMP PIPE

a 2.5″ V-band flange clamp assembly is included, along with a 2.5″ mandrel bent stainless 90deg elbow to begin your new dump pipe, which can either be run as a full new 2.5″ exhaust system or transitioned back into your existing system. A smaller 2.25″ dump pipe is available if this helps with exhaust fabrication.

OIL & WATER LINES

Included in the kit are stainless steel braided oil supply line with fittings to connect from Gemini engine oil gallery to turbo oil inlet. Aeroquip high temp hose and heat sheath, along with oil drain fittings for turbo and engine sump are in the kit.

Braided stainless steel -6AN water coolant lines all the fittings required to connect to heater hoses with clamps are supplied with all water cooled turbos.

NOTE: Oil cooled vs. Water cooled turbos

Oil cooled turbos perform exactly the same as water cooled turbos, the difference being the flow of oil cools the bearings in a oil cooled turbo, whereas a water-cooled turbo has a water jacket surrounding the turbo bearings for cooling.

After driving the car under boost, an oil cooled turbo engine needs to be idled for a minute or so to let cooler engine oil circulate and cool the turbo bearings. This is why turbo timers were invented, to let the engine idle without you sitting in the car. When using a water-cooled turbo, idling the engine after driving hard isn’t as critical, as the volume of water acts like a heat sink and cools the bearings.

One thing that people should keep in mind is that the standard G series engine is very strong. No strengthening modifications are required to use one of these kits, providing the engine is in decent condition to begin with, and the system is tuned properly, however if something isn’t right and you get serious detonation, you are guaranteed to break something. Boost levels that are safe to run depend on many factors, octane level of fuel, ignition timing, air temperatures, compression ratio, air/fuel mixtures, etc.

Stock G series engines usually have a static compression ratio of 8.7:1 or less, which is turbo friendly on high octane fuel.

ADD TO CART

ADD TO CART

Reviews

There are no reviews yet.